The weakest link in all wheel-driven speed record attempts is a surprising and obscure detail – tires (or “tyres” as the Brits and kiwis would call them)! Tyres can be one of the main points of failure on all vehicles, but are specifically troublesome on extremely high speed, wheel-driven vehicles. Therefore, we are literally re-inventing the wheel for Green Envy! Meet the “KiWheel”!

The very fastest cars are jet or rocket driven, and they run on solid aluminium wheels. The wheels are only used for stability and steering, not for driving. A wheel-driven vehicle such the Green Envy needs to have traction because the driving force is transmitted by the wheels to the ground. That means that the wheels have to have a high-friction surface such as rubber, or it has to have a tread pattern that cuts into the surface and gives good grip, like your running shoes. People have tried to run solid metal wheels with a tread pattern cut into the metal, but without great success. We believe the tread has to be flexible, so it both creates a contact patch and cut through the loose salt on the surface. Being flexible might also help to “shed” the salt that sticks to the wheel.

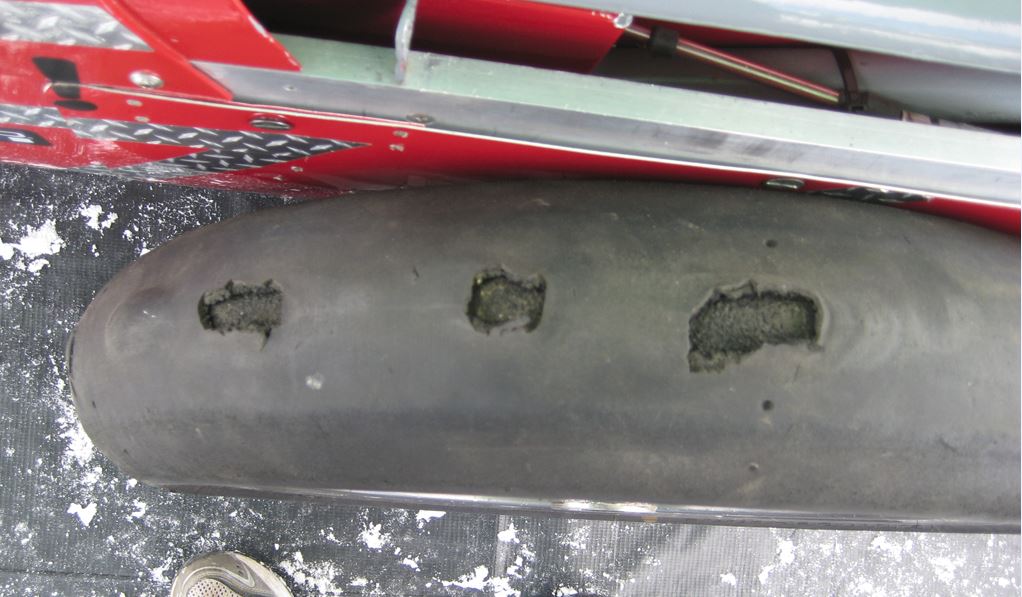

Pneumatic tyres (meaning regular, air-pumped tyres) have been used for wheel-driven land racing vehicles up to ~820 km/h (~510 mph), but are often not performing to a satisfactory level above ~600 km/h (~370 mph). They routinely overheat, delaminate, and often catastrophically fail. The photo below shows that KillaJoule tyre that delaminate at 343 km/h (213 mph). Luckily it held together and held air so I could come to a safe stop, but it was certainly scary! That was not just any old motorcycle tyre, but a high quality racing tyre. After that experience, we upgraded to Goodyear land racing tyres, but even the Goodyear tyres are only good for a bit more than 500 km/h (310 mph).

For low-budget teams like myself, it is difficult to find tyres that perform well above 500 km/h (~310 mph). With a target speed for the Green Envy of at least 605 km/h (376 mph – current overall motorcycle record), we have to find another solution. That means, we are literally re-inventing the wheel! The KillaJoule was initially used as the test platform for this development work, but with it retired since 2019, the Green Envy will be used.

This is the old front tire from the KillaJoule. It is a road-racing tire, but it couldn’t take the speed and the weight. It overheated and de-laminated at 213 mph (343 km/h). It was a quite scary moment when a veil of smoke came into the cockpit… Amazingly enough, the tire is still holding air. We upgraded to land racing tires the next year, regular racing tires had reached their limit. We are now approaching a similar crossroads, and it is time to completely re-invent the wheel.

So, how to you fund wheel research as a private team? Luckily, I managed to snag one of the sought-after “New Staff” research grants at the University of Auckland in March 2018. That gave me NZ$ 30,000 (~US$ 20,000) to work on developing new wheels over the next two years. It wasn’t a large amount of money to be research, but I am used to operate on an extremely tight budget so this was awesome from my perspective! The idea was to design a solid metal wheel with polymer (rubber) tread elements for traction for speeds exceeding 1000 km/h (620 mph).

The wheels made on the university grant were raced at Lake Gairdner salt flats in 2019. The results from that testing is found further below, but first a step back in time.

The 1st prototype

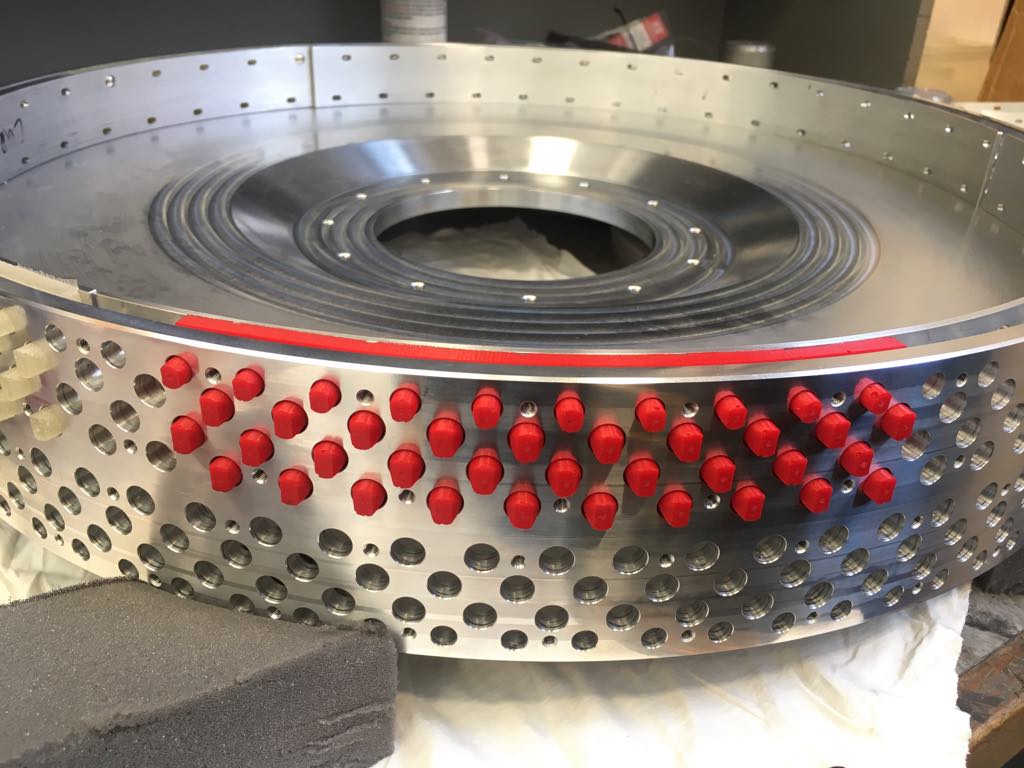

In 2017, we ran a first prototype wheel at Bonneville, which is shown below. This aluminum wheel has 3D printed tread elements made from polyurethane (“NinjaFlex” filament, printed on a LulzBot printer). The aluminum billet came from ALRECO in Henderson, Colorado which Steve Ciciora beautifully machined the wheel in his garage in his spare time (Thank you! Thank you! Thank you!) and I 3D printed the rubber elements. The wheel was beautiful, and worked well except that a few of the rubber pieces fell out. I had some last minute problems with the printing (probably because an incorrect cooling fan setting on the printer). That made some of the pieces come out a touch small, and they were pushed back into the wheel at speed. Nevertheless, we learned a lot and the design shows promise for the future. Below are some photos from the making of this first prototype wheel.

The solid aluminum wheel, machined by Steve Ciciora in his garage(!) in his spare time. That’s a true friend!

And the 3D printed rubber pieces!

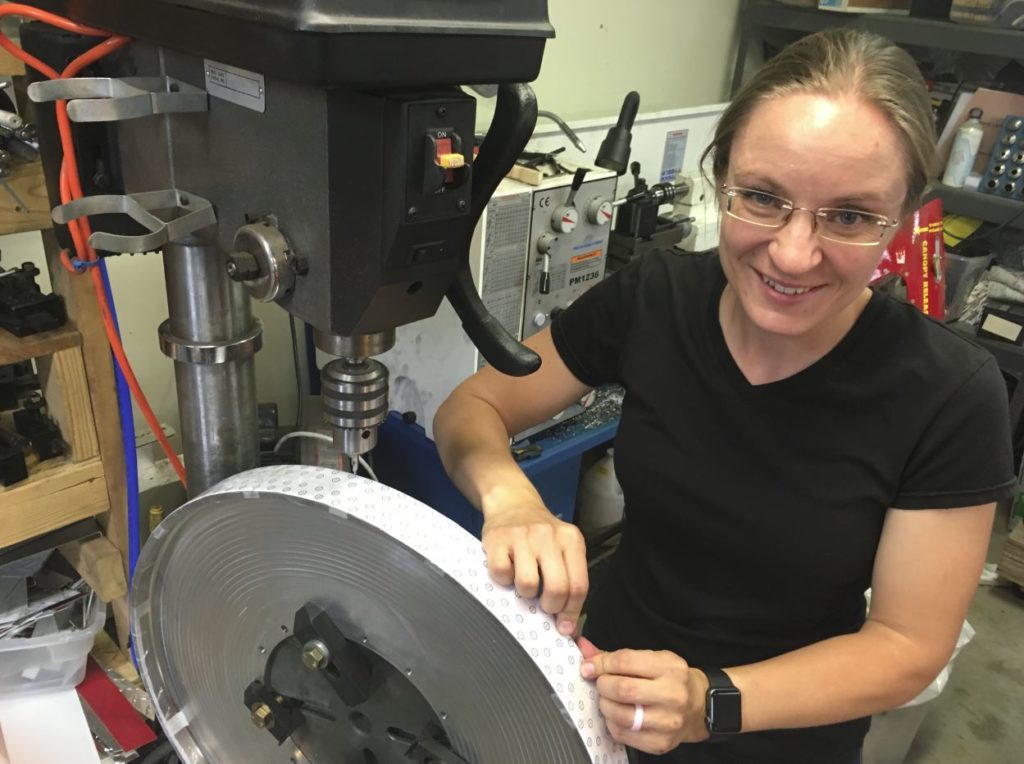

Bill and I drilled 400 (!) holes in the wheel, which took us almost a whole day.

The 3D printed tread elements were then threaded through the holes and pulled into place. That took almost another full day of work.

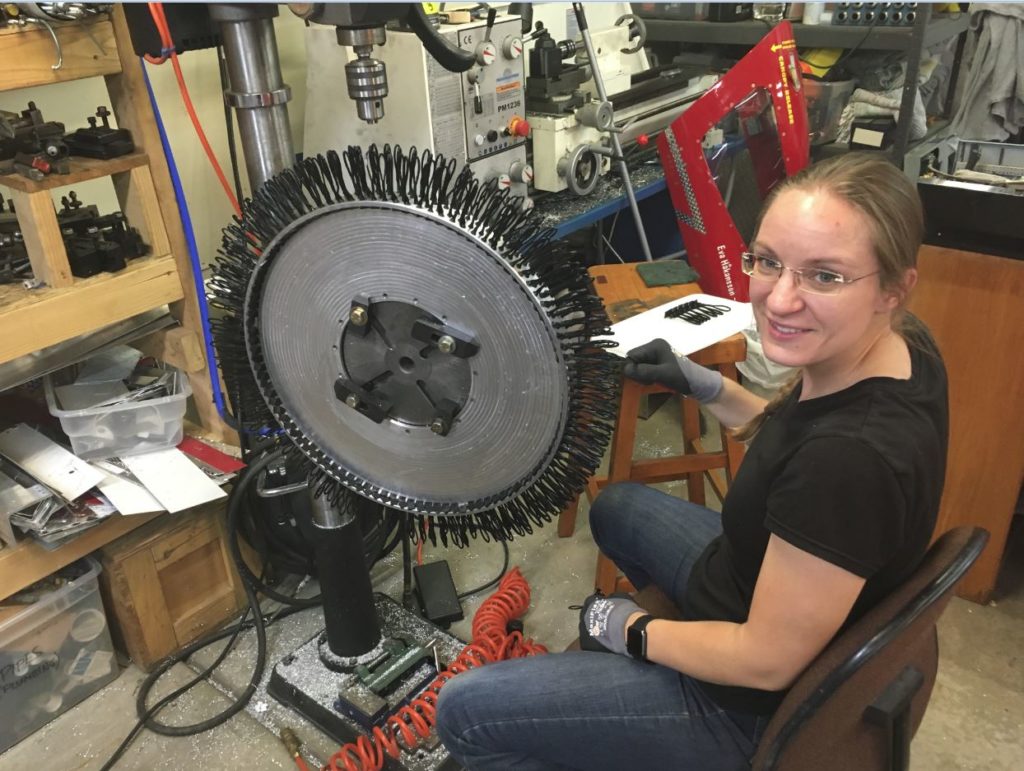

When finally in place, the pull handles were cut off, leaving rubber “nubs” sticking out of the wheel.

Just in time for Bonneville (literally the evening before we loaded up and drove to Bonneville), the wheel was finished and installed.

Arriving at Bonneville, the new wheel had to be approved by the technical inspectors. We didn’t have a clue what they would think about this innovative design, so I had armed myself to the teeth with finite element models and engineering calculations to be able to answer any concerns raised by the inspectors. But to my surprise, it flew right through the inspection. Nobody barely raised an eyebrow, I guess they are used to innovative designs.

I ran the experimental wheel during my first “shakedown” run. Due to a very rough track, I didn’t exceed ~260 km/h (~160 mph). We consider the test successful, but we ran into a problem we hadn’t expected. We were worried that the rubber elements would fly out due to the centripetal force, but it turned out that some of them were actually pushed inwards. Some of the printed rubber elements had come out a touch too small. We believe the printing problem it was an incorrect cooling fan setting on the printer. We had upgraded the printer with fans of our own design, and I accidentally used the default setting and not the reduced setting needed with the upgraded fans. That made the printing temperature too low, giving the melted rubber a higher viscosity. With the higher viscosity, the printer wasn’t able to feed out enough filament. The result was that some of them were a tiny bit skinnier than others, making them being pushed back into their holes after just a little bit of wear.

We concluded that we had learned what we could learn from the test, and we didn’t want to spread rubber pieces all over Bonneville (littering is illegal at Bonneville, you cannot leave anything behind, including vehicle parts). We mounted our regular sidecar wheel with a pneumatic tire and continued to race, knowing what we needed to do when we were back home again.

The 2nd prototype

Jump forward a year – and the opportunity to do something much better presented itself. As a new staff member at the University of Auckland I could apply for a “New staff” research grant. I applied in March 2018 – and it was approved! NZ $30,000 (about US $20,000) isn’t a whole lot of money for a research project, but it was certainly better than a poke in the eye and would be enough to make a set of wheels.

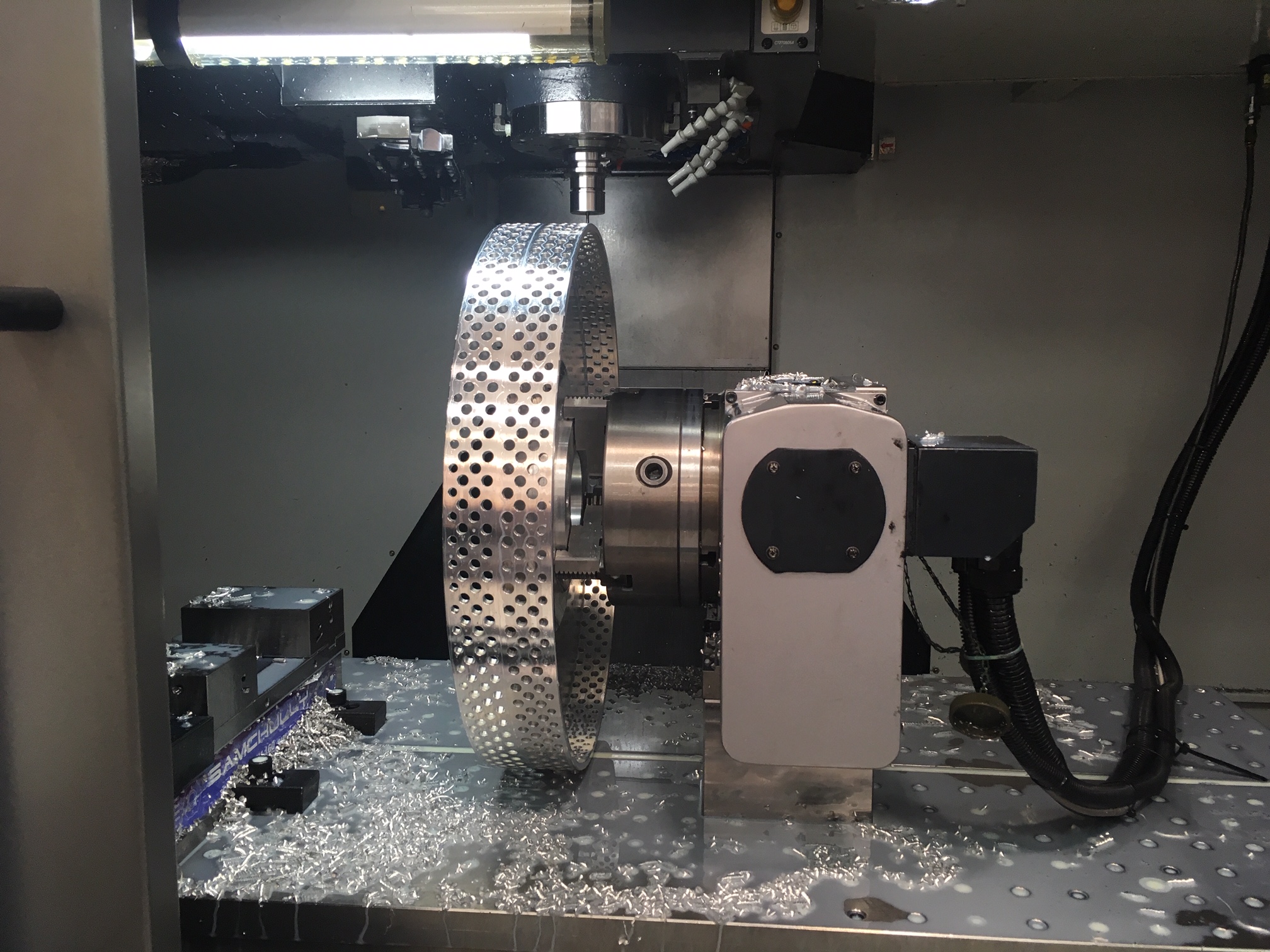

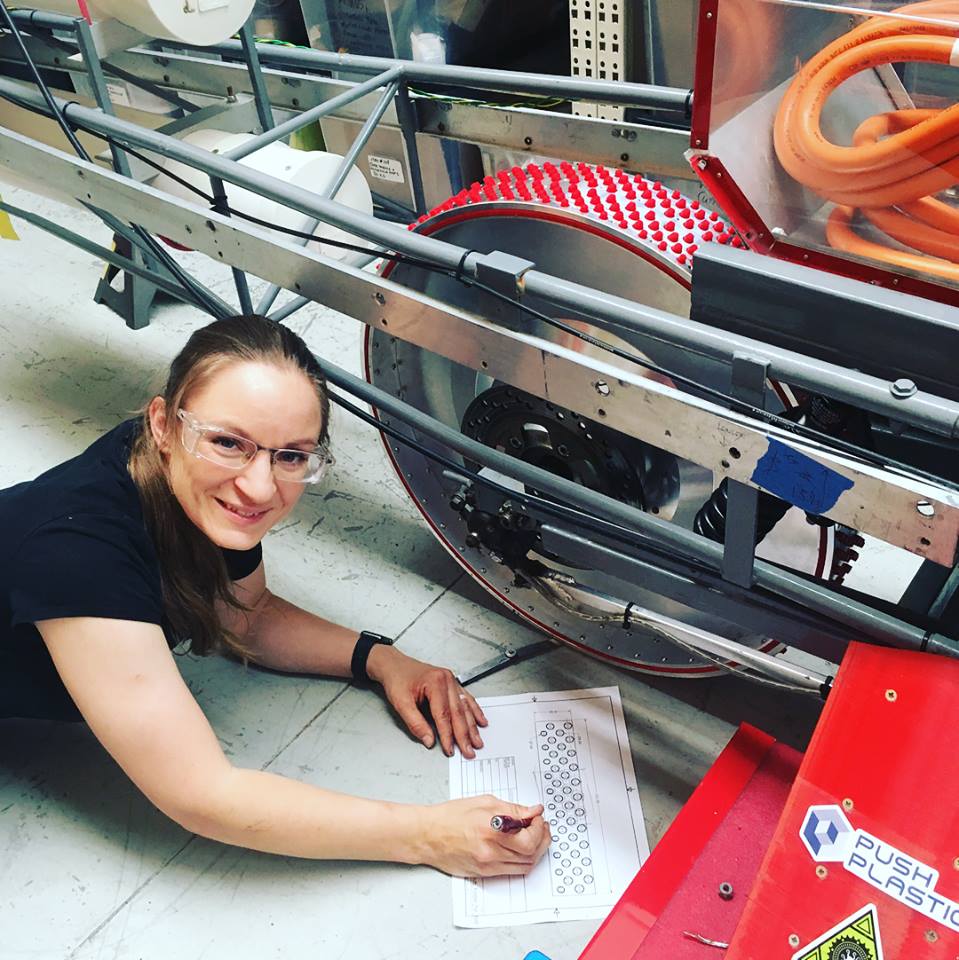

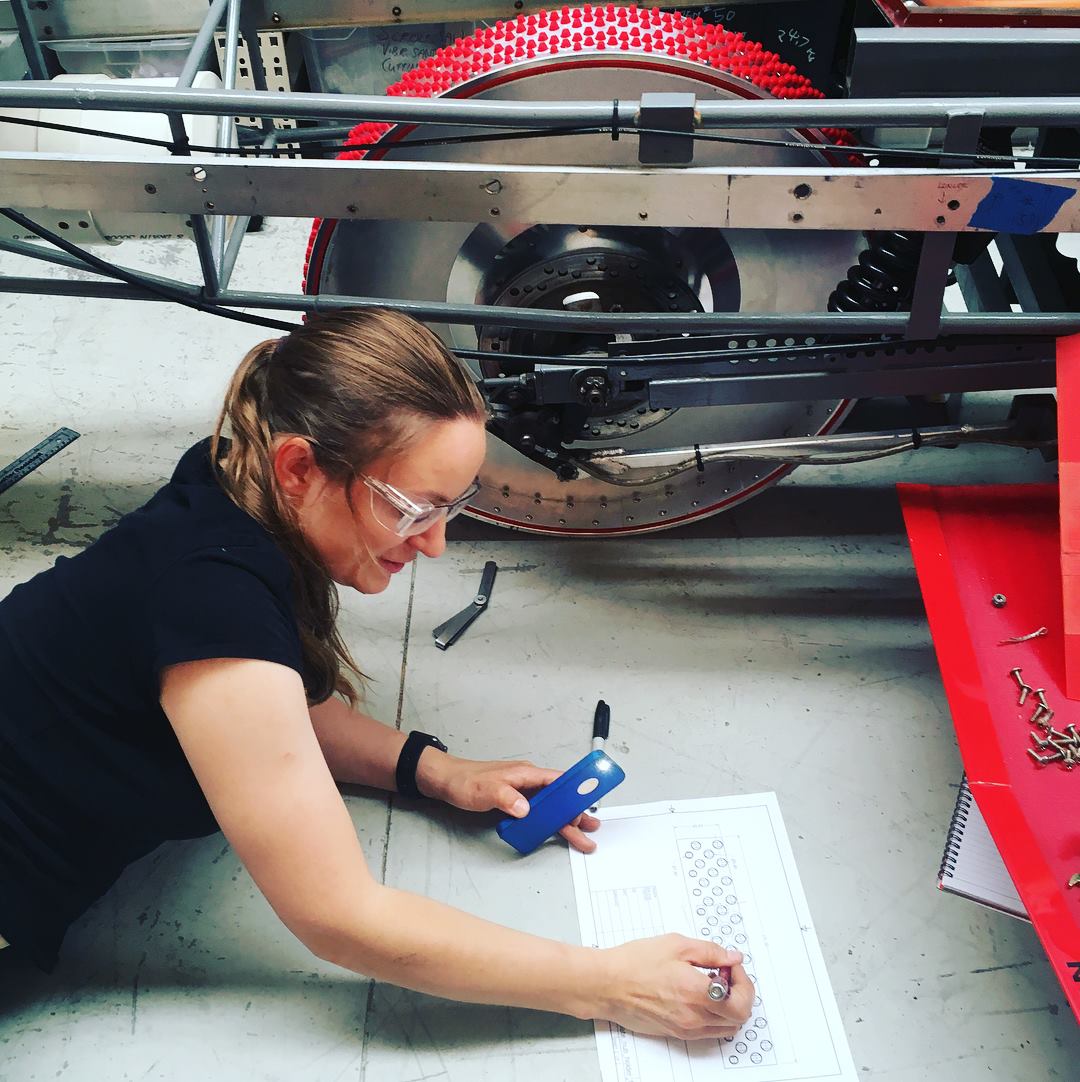

A set of three wheels (front, rear, and sidecar) where manufactured. The university machine shop made the wheels, while I made the rubber tread elements from industrial grade polyurethane. I 3D printed plugs, then cast molds in silicone rubber, and then cast the polyurethane parts in the silicone molds.

Bill and I designed the new wheel in Autodesk Inventor. Thanks to the use of CAD, the different components could be manufactured in different places, and still fit together perfectly in the end.

First test assembly. All parts fit perfectly together, thanks to being fully designed in CAD.

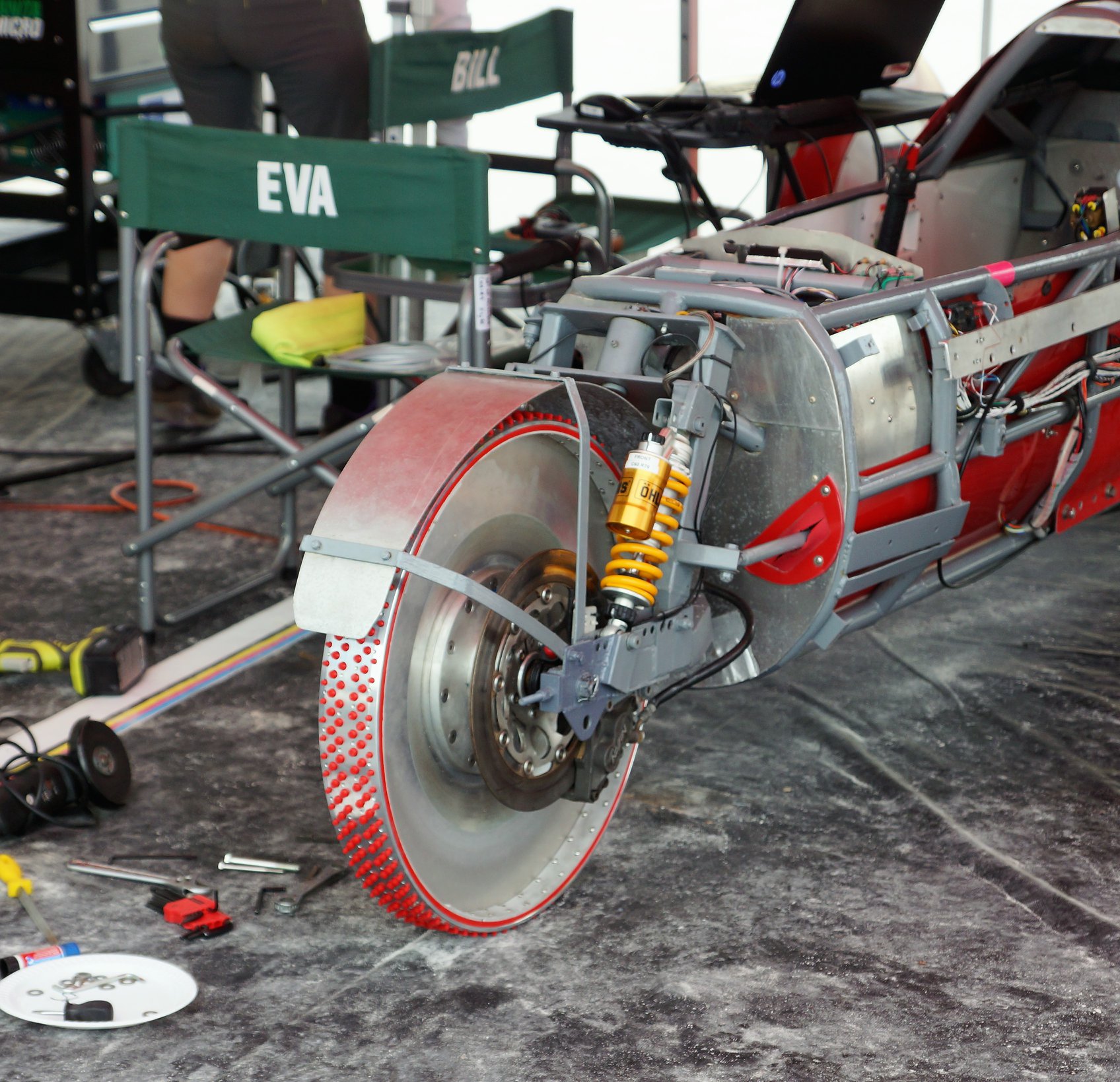

The rear wheel installed on the KillaJoule. I think it looks like something NASA would have designed for the Mars rover. The only difference is that NASA’s design probably would have left a message in morse code behind it. 😉

One of the most important design considerations was the contact patch, and it was exactly what we had predicted it would be.

The true test for the KiWheels was “the great white dyno” – the Lake Gairdner Salt Flats in South Australia. The new “KiWheels” were tested in Australia in March 2019 with very good results. There is – as always – improvements to be done, but they show a lot of promise. You can read about the results in Australia HERE.

Last minute assembly of the sidecar wheel by Crew Chief Steve Lovell.

On the starting line with the KiWheel on the front. We ran all three wheels, but not at the same time. The front wheel was first out.

And she is off! On course with the KiWheel on the front.

The Australia event was as successful as one can hope for. The KiWheels showed great potential and – most importantly – held together at speed! The sidecar worked the best while front and rear positions were plagued by severe vibrations due to insufficient suspension design. We took the sidecar wheel to 236 mph (380 km/h) without any problem. That is “only” halfway to our target speed of 400+ mph, but a very successful test.

I have during 2019 had two teams of final year engineering students working on improving both the wheel design and the suspension design. Summer and Dorsa have come up with a new tread design, while Anis and Halim have pinpointed the suspension issues. All these findings has been implemented in the Green Envy. I have good hopes that the KiWheels will be very successful on the Green Envy, and present a huge increase in land speed safety by eliminating the hazards associated with tire blowouts.

Another upgrade for the Green Envy is that the red rubber inserts that I made myself have been replaced with professionally made inserts by Vulkoprin in Belgium. Vulkoprin makes the world’s fastest roller-coaster wheels, and they used the same high performance polyurethane rubber for the Green Envy wheels. As you know, the pandemic and severe weather have severely delayed any record attempts, but our time will come and I have big hopes for the future of the KiWheels!

Stay tuned for more updates!

Flat out into the future – faster and safer!