Posted June 12, 2019

It is one thing to design a racing vehicle in CAD (computer aided design), it is whole different thing to actually build it! 4 meters long and made up of dozens and dozens of tube segments, this is like assembling a 3D puzzle!

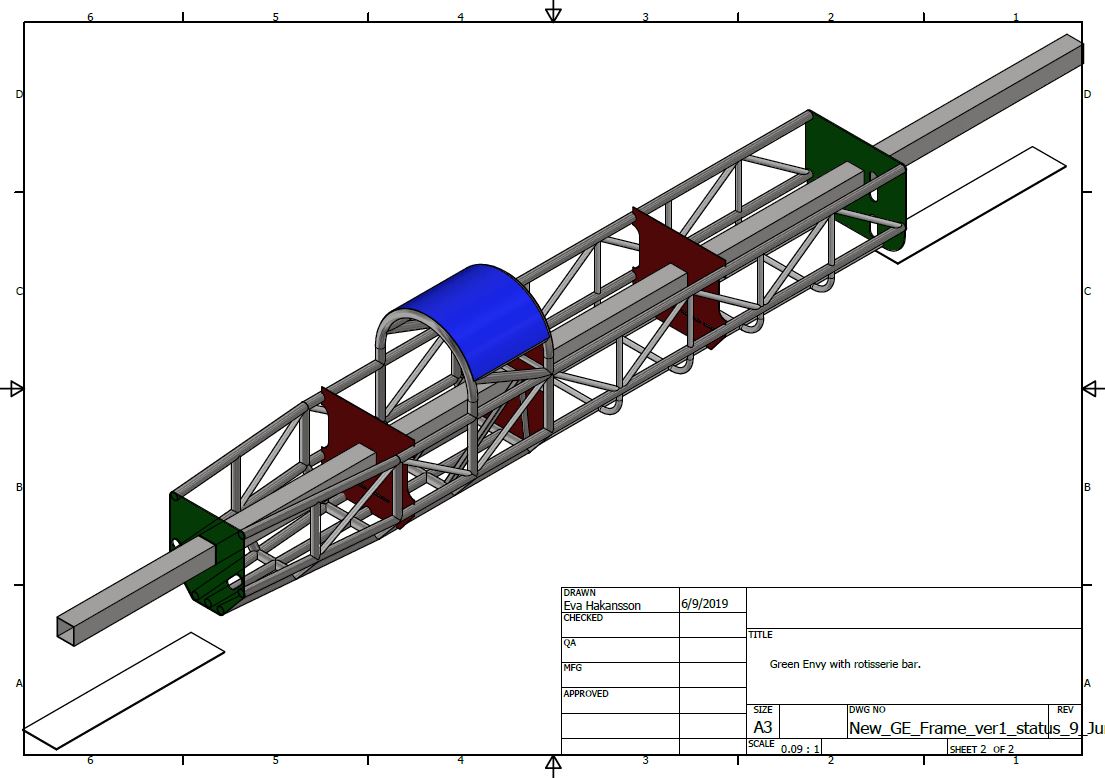

Luckily, Peter Hopperus at Axis Industrial is helping us fabricate the frame, and he suggested this rotisserie chicken approach! The front and rear bulkheads (in green) will be welded in and stay in the frame, so will the firewall and the roll cage cap (blue). The two additional red sections will be used as jigs while welding, and will then be removed. As will the long square “rotisserie bar”, of course.

The long bar will be connected to two stands so we can rotate the frame and weld in a convenient orientation. The bar is placed in the center of gravity of the frame, so it doesn’t want to tip one way or another. We built the KillaJoule on a table, but this is much smarter! I wish I had come up with the idea myself… :-S

If everything goes according to plan, all the tubes you see in the drawing will be sent off and be laser cut next week. I am so excited! We notched all the tubes by hand for KillaJoule, and it is an awful lot of work and it never fits that nicely. With laser cutting, the fit will be perfect and the welding will be easier, better, and faster.

// Eva